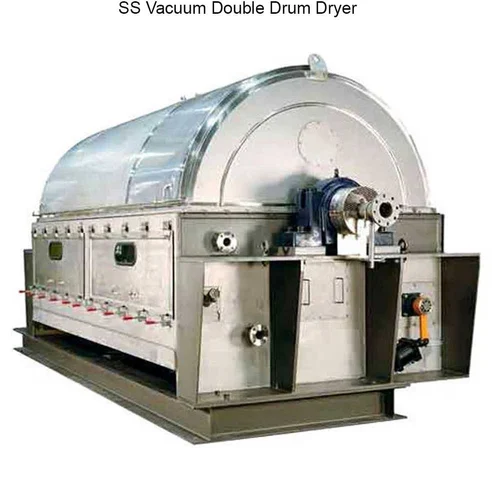

SS Vacuum Double Drum Dryer

-

- Usage/Application Industrial

- Automation Grade Automatic

- Surface Finish Coated

- Material Stainless steel

- Brand Arrowhead Seperation Engineering Limited

- Country of Origin Made in India

- Design Customized

- Frequency 50Hz

- Product Form Powder

- Capacity 90 Ton/H

The system consists of Vacuum Double Drum Dryer, Condenser, Receiver, Feed Vessel with Valve, Accessories, Skid etc. The Double Drum Dryer except the drive is enclosed in a suitable cylindrical enclosure having quick opening doors at both the ends. The enclosure is jacketed, to which low pressure steam is supplied. This ensures that there is no condensation of vapour generated during the drying operation, on the walls of the enclosure. The drive to the double drum dryer is fixed outside the enclosure. The vapours escaping from the dryer enclosure are condensed in a suitable shell and tube type condenser and collected in a suitable receiver. Material is fed to the drum dryer because of vacuum suction. The valve provides requisite control.

Features

- Suitable for handling liquid or pasty feeds.

- Suitable for materials required low temperature drying.

- Product is in the form of powder.

- Uniform drying due to uniform application of film. Medium/high range capacities.

- Very high thermal efficiency.

- Continuous operation.

- Compact installation.

- Heat sensitive material can be dried.

- Heating medium can be either low pressure steam or hot water.

- Solution containing solvents can be dried with complete recovery of solvent in continuous manner.

- Totally enclosed machine and no exposure to the atmosphere.

Typical Applications:

- Heat Sensitive Materials.